hide

Why ESG in Supply Chain Starts With Damage Prevention

1. The Overlooked Environmental Cost of Damaged Goods

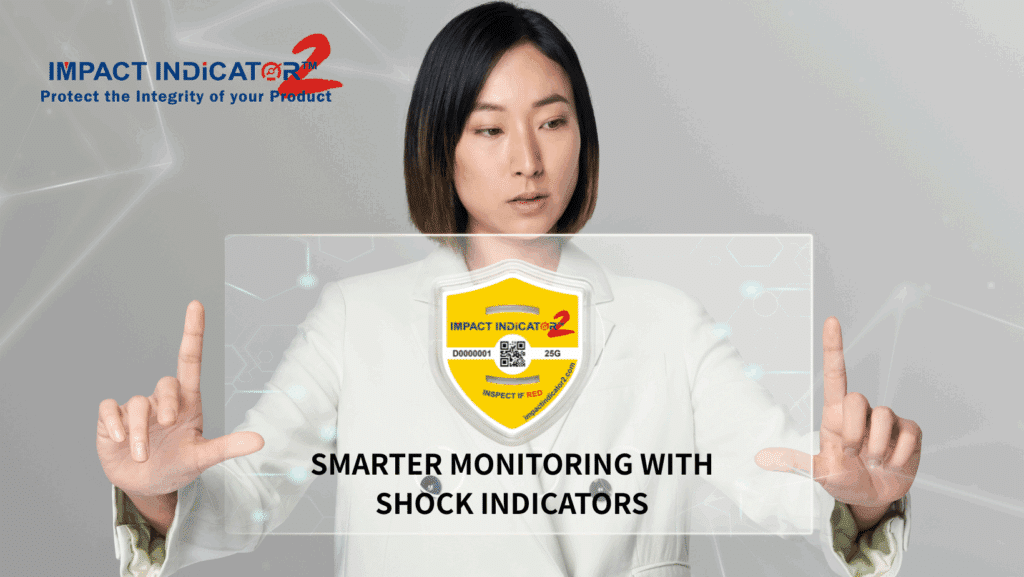

2. Why Traditional Packaging Isn’t Enough

3. Smarter Shock Monitoring with G Shock Indicators

4. From Reactive to Preventive: A Greener Strategy

5. Choosing the Right Packaging Indicators for Impact/Shock Monitoring

In today’s global logistics ecosystem, brands are under more pressure than ever to meet ESG goals—especially in supply chain management. However, while many companies focus on sustainable packaging or low-emission transportation, a hidden environmental villain lurks behind the scenes: product damage during shipping.

Every time a product gets damaged, it triggers a cascade of waste—repackaging, remanufacturing, reverse logistics, even landfill dumping. Not only does this erode your bottom line, but it also quietly sabotages your ESG in supply chain efforts.

So what can be done? Let’s uncover the real impact of damaged goods—and how packaging indicators like shock label indicators , g shock indicators, can help you fix the leak before it spills.

Damaged shipments aren’t just an annoyance—they’re a resource sink. Each broken item represents a product that required:

When that product ends up returned, discarded, or remade, your company’s carbon footprint silently doubles.

And that doesn’t just hurt your wallet—it puts your ESG in supply chain scores at risk.

🌱 Did you know? Studies estimate that up to 3% of shipped goods arrive damaged—translating into millions of tons of wasted material annually.

It’s tempting to just “add more bubble wrap.” But excessive packaging is not a sustainable solution. Overdesign leads to:

Instead, the smarter approach is impact transparency: knowing exactly when, where, and how your product experiences shock during transport.

This is where tools like shock label indicators come into play. They don’t prevent shock, but they show you when it happens—so you can identify problems in your logistics chain and fix them for good.

Modern shock indicators like the g shock indicator or tamper-proof packaging indicators are designed for one purpose: shock monitoring.

Placed on crates, pallets, or sensitive equipment, these low-cost tools record when a certain force threshold is exceeded. Some models even log the shock timing for forensic-level insights.

Benefits include:

✅ Proof for warranty or damage claims

✅ Accountability for third-party logistics (3PL) partners

✅ Data to optimize routes or carrier selection

✅ A tangible step toward better ESG in supply chain performance

Preventing damage before it happens is the ultimate sustainability move. Companies that integrate shock monitoring into their operations can expect:

In essence, using shock label indicators isn’t just about safety—it’s about responsibility.

♻️ Proactive monitoring is leaner, greener, and smarter. And it proves that your brand cares—about your customers and the planet.

Not all shock indicators are created equal. Look for devices that offer:

If you're aiming for ESG in supply chain credibility, your monitoring tools should match your sustainability ambitions.

Product damage may not be the flashiest ESG topic—but it’s one of the most easily fixable. By switching to a preventive model with shock indicators and shock monitoring tools, your business can shrink its environmental footprint, avoid unnecessary costs, and improve your supply chain transparency.

Ready to align your logistics with your values?

We offer:

👉 Contact us today and make damage prevention part of your ESG story.

Q1: How does product damage affect ESG in supply chain?

A: Damaged goods lead to material waste, increased emissions from reverse logistics, and higher landfill volumes—all of which undermine environmental sustainability goals.

Q2: Are shock indicators expensive to implement?

A: No. Most shock indicators are affordable, especially compared to the cost of replacing damaged products. They offer high ROI in damage reduction and data insight.

Q3: Can shock indicators replace protective packaging?

A: They complement it. Indicators help you verify if your packaging is working and guide improvements, reducing the need for over-packaging.

Q4: What’s the difference between g shock indicators and other packaging indicators?

A: G shock indicators measure specific impact thresholds (e.g., 25G or 50G), while other indicators may simply show tilt, tampering, or cumulative shock events.

Q5: Do shock indicators support ESG reporting?

A: Yes. By reducing product loss and enabling supply chain transparency, shock indicators contribute to measurable ESG performance improvements.